技术中心Service

分类

核心技术

CORE TECHNOLOGY

核心能力:技术工艺

Core competence: Technical process

正火 粗车/精车

粗车/精车 热前(滚,倒,剃,插齿,倒尖角)

热前(滚,倒,剃,插齿,倒尖角) 压配/焊接

压配/焊接 热处理

热处理 热后磨

热后磨

正火Normalizing

粗车 / 精车 Low Precision Machining / High Precision Machining

热前(滚,倒剃,插齿,倒尖角)Before Heat Treatment (Hobbing, Chamfering, Shaving, Milling, Chamfering)

压配 / 焊接 Press to Match / Welding

热处理 Heat Treatment

热后磨 Grinding after heat treatment

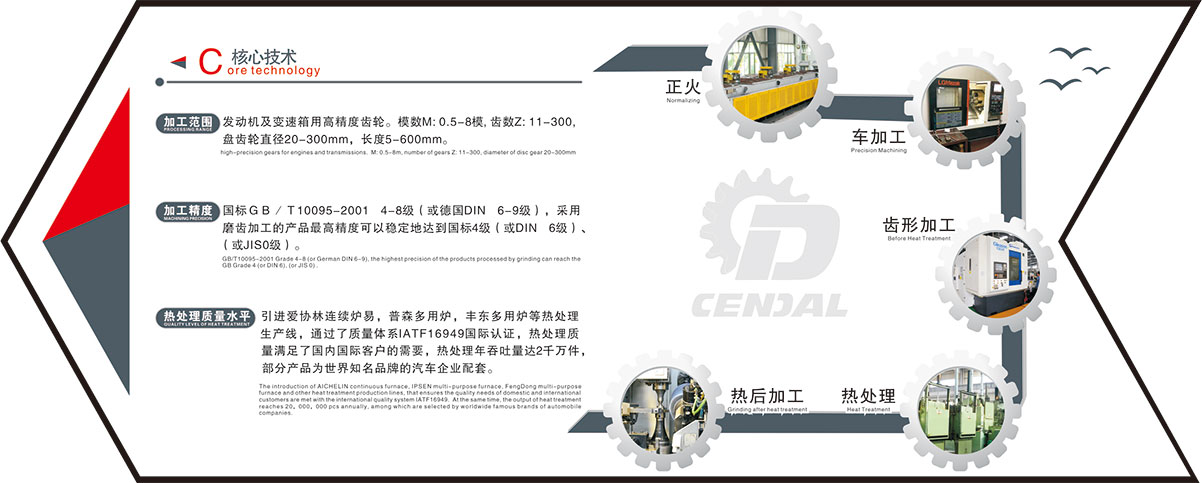

加工范围:发动机及变速箱用高精度齿轮。磨速M: 0.5-8mm, 齿数Z: 11-300, 盘齿轮直径20-300mm

加工精度:国标GB/T10095-2001 4-8级(或德国DIN 6-9级),采用磨齿加工的产品最高精度可以稳定地达到国标4级(或DIN 6级)、(或JIS0级)。

Processing range: high-precision gears for engines and transmissions. Grinding speed M: 0.5-8mm, number of gears Z: 11-300, diameter of disc gear 20-300mm

Machining precision: GB/T10095-2001 Grade 4-8 (or German DIN 6-9), the highest precision of the products processed by grinding can reach the GB Grade 4 (or DIN 6), (or JIS 0) .

热处理质量水平:引进爱协林连续炉, 易普森多用炉,丰东多用炉等热处理生产线,通过了质量体系TS16949国际认证,热处理质量满足了国内国际客户的需要,热处理年吞吐量达1.2万件,部分产品为世界知名品牌的汽车企业配套

Quality level of heat treatment: The introduction of AICHELIN continuous furnace, IPSEN multi-purpose furnace, FengDong multi-purpose furnace and other heat treatment production lines, that ensures the quality needs of domestic and international customers are met with the international quality system TS16949. At the same time, the output of heat treatment reaches 12,000 pcs annually, among which are selected by worldwide famous brands of automobile companies.

Core competence: Technical process

正火

粗车/精车

粗车/精车 热前(滚,倒,剃,插齿,倒尖角)

热前(滚,倒,剃,插齿,倒尖角) 压配/焊接

压配/焊接 热处理

热处理 热后磨

热后磨正火Normalizing

粗车 / 精车 Low Precision Machining / High Precision Machining

热前(滚,倒剃,插齿,倒尖角)Before Heat Treatment (Hobbing, Chamfering, Shaving, Milling, Chamfering)

压配 / 焊接 Press to Match / Welding

热处理 Heat Treatment

热后磨 Grinding after heat treatment

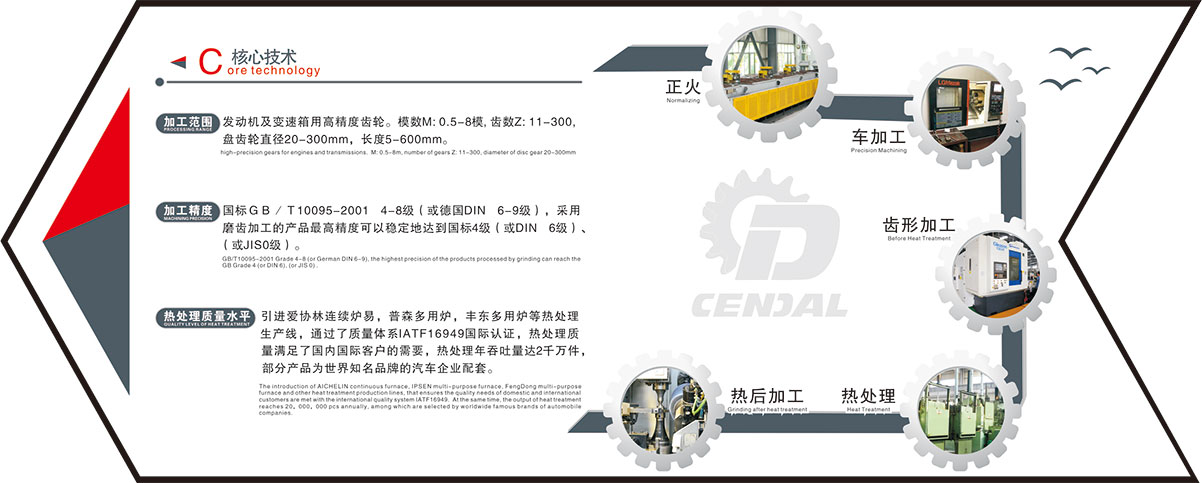

加工范围:发动机及变速箱用高精度齿轮。磨速M: 0.5-8mm, 齿数Z: 11-300, 盘齿轮直径20-300mm

加工精度:国标GB/T10095-2001 4-8级(或德国DIN 6-9级),采用磨齿加工的产品最高精度可以稳定地达到国标4级(或DIN 6级)、(或JIS0级)。

Processing range: high-precision gears for engines and transmissions. Grinding speed M: 0.5-8mm, number of gears Z: 11-300, diameter of disc gear 20-300mm

Machining precision: GB/T10095-2001 Grade 4-8 (or German DIN 6-9), the highest precision of the products processed by grinding can reach the GB Grade 4 (or DIN 6), (or JIS 0) .

热处理质量水平:引进爱协林连续炉, 易普森多用炉,丰东多用炉等热处理生产线,通过了质量体系TS16949国际认证,热处理质量满足了国内国际客户的需要,热处理年吞吐量达1.2万件,部分产品为世界知名品牌的汽车企业配套

Quality level of heat treatment: The introduction of AICHELIN continuous furnace, IPSEN multi-purpose furnace, FengDong multi-purpose furnace and other heat treatment production lines, that ensures the quality needs of domestic and international customers are met with the international quality system TS16949. At the same time, the output of heat treatment reaches 12,000 pcs annually, among which are selected by worldwide famous brands of automobile companies.